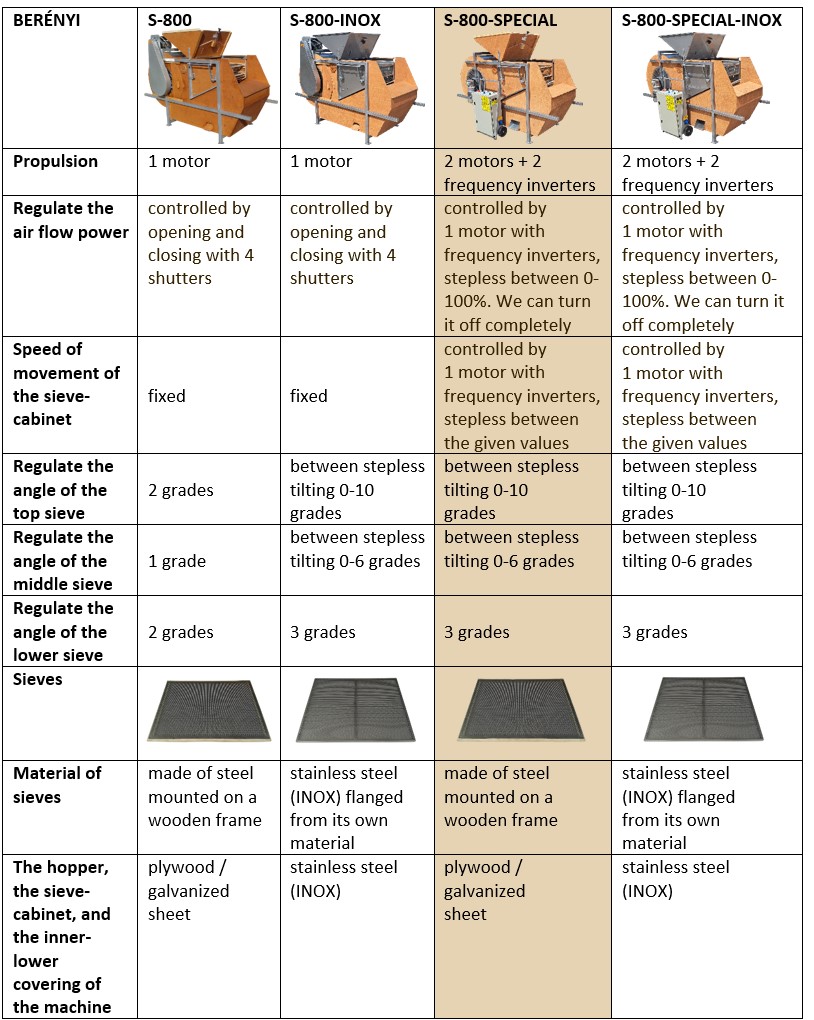

BERÉNYI S-800-SPECIAL

SEED CLEANING MACHINE: effective cleaning and classification even for special, small seeds

Its cleaning capacity is 800-1500 kg per hour of wheat!

What kind of seeds is the BERÉNYI S-800-SPECIAL Seed cleaning machine ideal for cleaning?

|

Cereals: wheat, spelt, |

Legumes: soybeans, beans, peas, lentils, chickpeas |

Oil and fiber crops: sunflower, hemp seeds, pumpkin seeds, mustard, rape, flax, poppy seeds, camelina sativa |

Forage crops: alfalfa, clovers, vetch, grass seeds |

|

Flower seeds: chamomile, other flower seeds |

Medicinal herbs: lavender flower, tea leaves, fennel, others |

Vegetable seeds: onions, carrots, lettuce, cabbage, broccoli, others |

Herbs: thyme, sage, oregano, others |

Designed for reliability and efficiency

Our machines represent an excellent choice both in terms of return on investment and from the practical users perspective.

Technical specifications

Weight: 140 kg

Dimensions (length x width x height): 2160x1000x1530 mm

1 motor: 230 V; 0,37 KW

2 motor: 230 V; 0,37 KW

Unique concept

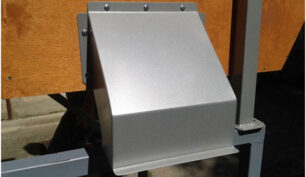

The seed cleaner is controlled via a separate electrical control cabinet, which can be placed conveniently next to the machine for easy operation.

The control cabinet houses two frequency converters, allowing independent regulation of the speeds of the two drive motors. This enables stepless adjustment of the airflow strength and the sieve-cabinet movement speed.

Since the ventilatior’s fan and the sieve-cabinat are operated by independent motors and frequency converters, it is possible to apply completely unique, most efficient, and optimal settings tailored to the material being cleaned.

Operates efficiently and at low noise levels. The airflow strength can be regulated within a 0-100% range using the drive motor equipped with a frequency converter. This ensures complete air passage through the material being cleaned, and precise air regulation enhances the performance of seed cleaning.

It removes dust, husks, light seeds, and other lightweight materials, ensuring excellent efficiency for cleaning all types of seeds, flowers, and foliage.

It classifies and cleans the seeds based on weight and size. The speed of the sieve-cabinet movement can be precisely adjusted using the drive motor equipped with a frequency converter, ensuring maximum utilization of the cleaning effect of the sieves.

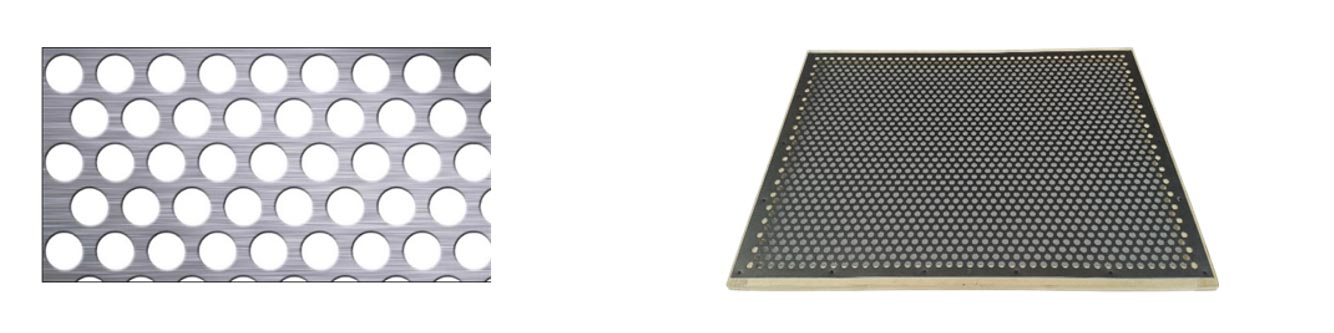

Among the three sieves in the sieve-cabinet, the tilt angle of the upper and middle sieves can be adjusted steplessly, while the tilt angle of the lower sieve can be adjusted in three stages. The sieves can be quickly and easily replaced in a short amount of time. The S-800-SPECIAL Seed Cleaner comes equipped with 3 perforated sieves mounted on frames, ready for operation.

It is made with a stable, welded steel frame structure with powder coating, combined with laminated birch plywood panels.

The laminated birch plywood panel:

- Is moisture and insect resistant,

- Ensures long lifespan for the machine, as laminated birch plywood withstands the vibrations of the sieves, has low resonance, operates at low noise levels, thereby providing a better working environment.

Due to the design of gravitational material flow, the filling-hopper is positioned at the highest point of the seed cleaner. Through the chute opening, the material to be cleaned flows across the entire width onto the sieve structure. This ensures that the material spreads evenly across the sieves, maximizing the utilization of the sieve surfaces.

How does the BERÉNYI S-800-SPECIAL Seed cleaner work?

- The material to be cleaned exits the filling-hopper through the chute opening and is directed by raising the chute to the upper sieve (clod-sieve) located in the machine’s sieve-cabinet by gravity.

- The material passing through the clod-sieve moves to the middle sieve (seed sieve), where larger impurities are separated along with the fraction removed from the clod-sieve. They exit the machine through a right-side opening.

- Material passing through the seed sieve reaches the lower sieve (dust-sieve), which separates fine impurities such as small seeds, weed seeds, and broken grains from the valuable seeds. These fine impurities exit the machine through a left-side opening.

- The cleaned material exits the machine through the first seed outlet at the front. Throughout the sieving process, the air circulation generated by the fan separates dust and light impurities from the valuable material and ejects them from the sieve-cabinet.

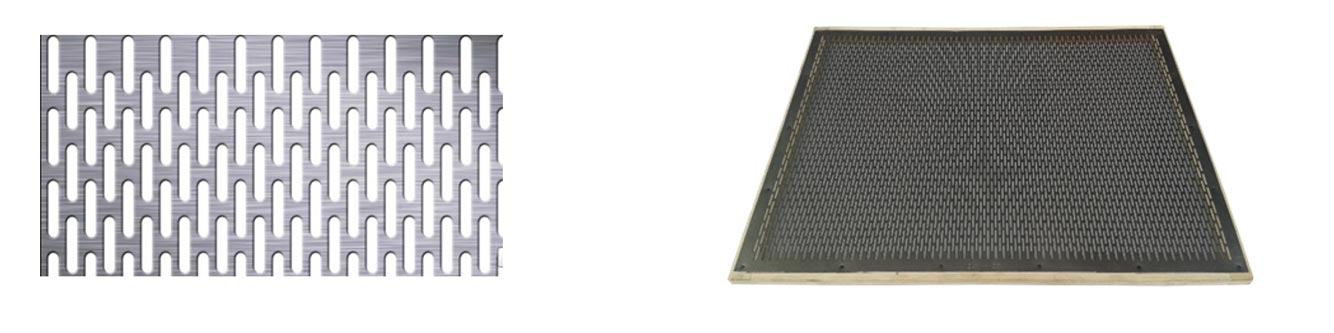

Choose perforated sieves for your BERÉNYI S-800-SPECIAL Seed cleaner!

Rv – round holes of the sieve

Diameter of the round holes Ø (mm): 1,0 1,2 1,5 1,8 2,0 2,2 2,5 2,8 3,0 3,5 4,0 4,5 5,0 5,5 6,0 6,5 7,0 7,5 8,0 8,5 9,0 9,5 10,0 11,0 12,0 13,0 14,0 16,0 17,0 18,0

Lv – oblong holes of the sieve

Stainless steel mesh on wooden frame ≠ (mm): 1,0 x 20 1,2 x 20 1,4 x 20 1,5 x 20 1,8 x 20 2,0 x 20 2,2 x 20 2,4 x 20 2,5 x 20 2,8 x 20 3,0 x 20 3,2 x 20 3,5 x 20 3,8 x 20 4,0 x 20 4,5 x 20 5,0 x 20 6,0 x 20 7,0 x 20 8,0 x 20

We can provide stainless steel mesh sieves below 1mm for cleaning small-sized, tiny seeds:

Stainless steel mesh on wooden frame ≠ (mm): 0,2 x 0,2 0,4 x 0,4 0,6 x 0,6 0,8 x 0,8 1,0 x 1,0

We are happy to assist you in determining the suitable size of perforated sieves for the types of seeds you want to clean!

Watch our S-800-SPECIAL Seed cleaner machine in action

Cornflower seeds cleaning

Crimson clover cleaning

Quinoa cleaning

Camelina sativa cleaning

Dame’s-violet seeds cleaning

Lavender flower cleaning